Pump House

I get the question quite often of what is in that building on #12. That building is what houses our irrigation system pumps, backflow preventer, meter, and tie in for our city water supply.

Why is it located there, and why don’t we move it are the other questions I get most often. It is located there because directly behind it is a 12in high pressure water line that feeds our irrigation from the Northern Ky Water District. That same line runs down #12 then heads back up to the road, and feeds most of Erlanger with water.

The question of why we don’t move it is mostly answered above, and there is no room to go back toward the road any due to the location of city water line. That is the only area on the golf course that we have the ability to tie into a main large enough to supply us with the water volume we need. Unfortunately, with a slice on #12 the pump house may still come into play even with the new system.

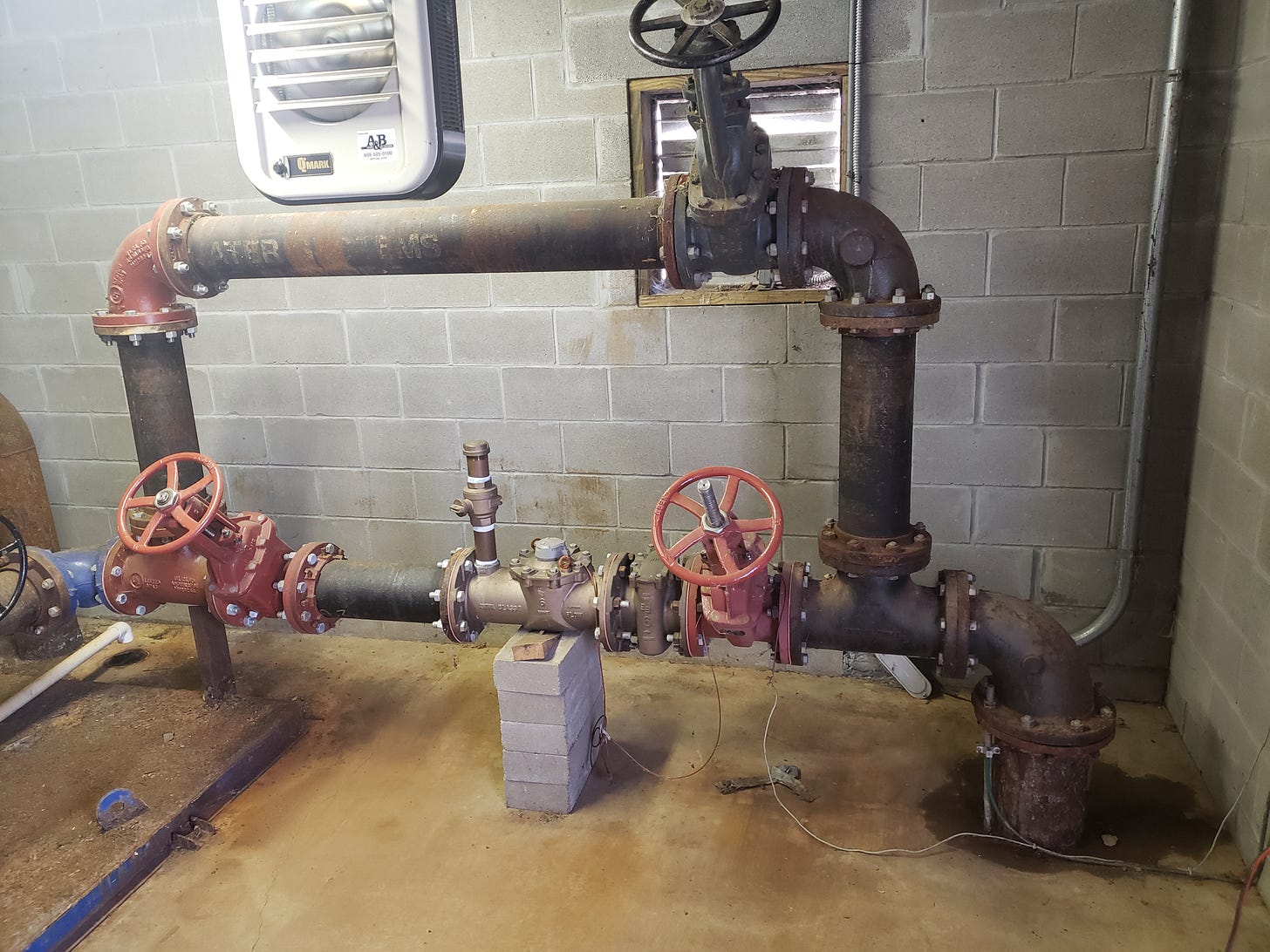

The picture above is the city inlet into the pump house. The large red valves are our main shut off valves for the system to isolate us from the city. The Brass piece in the middle of the two valves is the meter. None of this setup will change with the new system.

The picture above shows our back flow preventer, and the water line leaving the pump house going out to our current system. We currently do not use the pumps that are in there now. After years of issues and breakdowns, the decision was made not to invest in new pumps, but to pipe directly into our system from the city, using only the city pressure. This worked for our old system, we were able to still run around 600 gallons a minute, which gave us the ability to get everything watered overnight. With our new system we will be adding 374 total heads to the golf course. With these additional heads our irrigation consultant wants us to be up around 1200 gallons a minute, to ensure we can get everything watered overnight. That is the reason for the new pumps being installed this summer.

The picture above is an example of what our new pumps will look like. The entire system shows up on a skid and is slid into the pumphouse after the old pumps are removed. We will have two 25hp main pumps and a smaller maintenance pump.

These new pumps are all computerized with the ability to log into our pump station remotely to check on pressure, output, and various other things. If our pumps should ever have an issue an alert it sent to the pump manufacturing representative, and myself so that we can quickly troubleshoot and solve any problems.

This irrigation system is a large undertaking by the club, a much needed and appreciated one. By investing in a top-of-the-line system, and with routine maintenance, this system should last for decades.